LCA – EPD and the Stages in a Life Cycle Assessment

LCA (Life Cycle Assessment) and EPD (Environmental Product Declaration) are important tools that help businesses measure and declare the environmental impact of their products. By analyzing each stage from extraction, production, and use to recycling, businesses can optimize resources and reduce emissions. This provides a foundation for moving towards green manufacturing and meeting the demands of the international market.

1. What are LCA and EPD?

Life Cycle Assessment (LCA) is a scientific method for quantifying the environmental impacts of a product, from the raw material extraction phase to the end-of-life treatment. This method is standardized by ISO 14040 and ISO 14044 and serves as the foundation for global environmental reporting and certification tools.

An Environmental Product Declaration (EPD) is a transparent report that publicly discloses information about a product’s environmental impact based on the results of an LCA. An EPD is verified by a third party and published on international systems like EPD International (environdec.com). It provides value to businesses in building a green brand, meeting export requirements, bidding for green building projects, or for ESG certification.

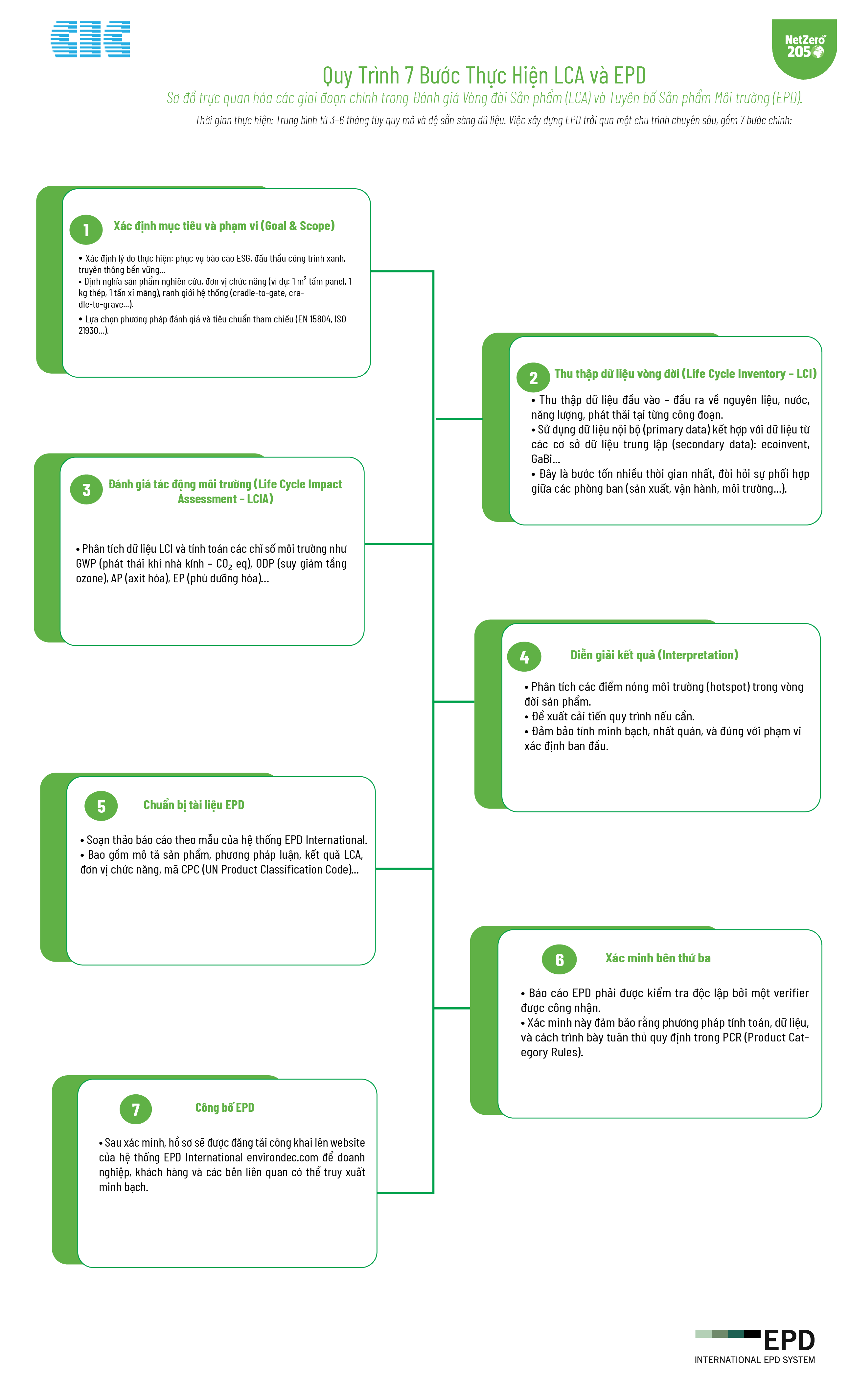

2. The Process of Implementing LCA and EPD

The average time to complete an LCA and EPD is from 3 to 6 months, depending on the scale and data readiness. Developing an EPD involves an in-depth cycle consisting of 7 main steps.

Step 1: Goal & Scope Definition

- Determine the reason for the assessment: for ESG reporting, bidding for green projects, sustainability communications, etc.

- Define the product under study, the functional unit (e.g., 1 m² of panel, 1 kg of steel, 1 ton of cement), and the system boundary (cradle-to-gate, cradle-to-grave, etc.).

- Select the assessment methodology and reference standards (EN 15804, ISO 21930, etc.).

Step 2: Life Cycle Inventory (LCI)

- Collect input-output data on raw materials, water, energy, and emissions at each stage.

- Use internal data (primary data) combined with data from neutral databases (secondary data) such as ecoinvent, GaBi, etc.

- This is the most time-consuming step, requiring coordination between various departments (production, operations, environmental, etc.).

Step 3: Life Cycle Impact Assessment (LCIA)

- Analyze the LCI data and calculate environmental indicators such as GWP (Greenhouse Gas Emissions – CO₂ eq), ODP (Ozone Depletion Potential), AP (Acidification Potential), EP (Eutrophication Potential), etc.

Step 4: Interpretation

- Analyze environmental hotspots in the product’s life cycle.

- Propose process improvements if necessary.

- Ensure transparency, consistency, and alignment with the initially defined scope.

Step 5: Prepare the EPD Document

- Draft the report according to the template of the EPD International system.

- Include a product description, methodology, LCA results, functional unit, UN CPC Code (Central Product Classification), etc.

Step 6: Third-Party Verification

- The EPD report must be independently checked by an accredited verifier.

- This verification ensures that the calculation methods, data, and presentation comply with the regulations in the relevant PCR (Product Category Rules).

Step 7: EPD Publication

- After verification, the EPD will be publicly uploaded to the EPD International system website, environdec.com, so that businesses, customers, and stakeholders can access it transparently.

The Environmental Product Declaration for Chinfon cement products published on the EPD International system website

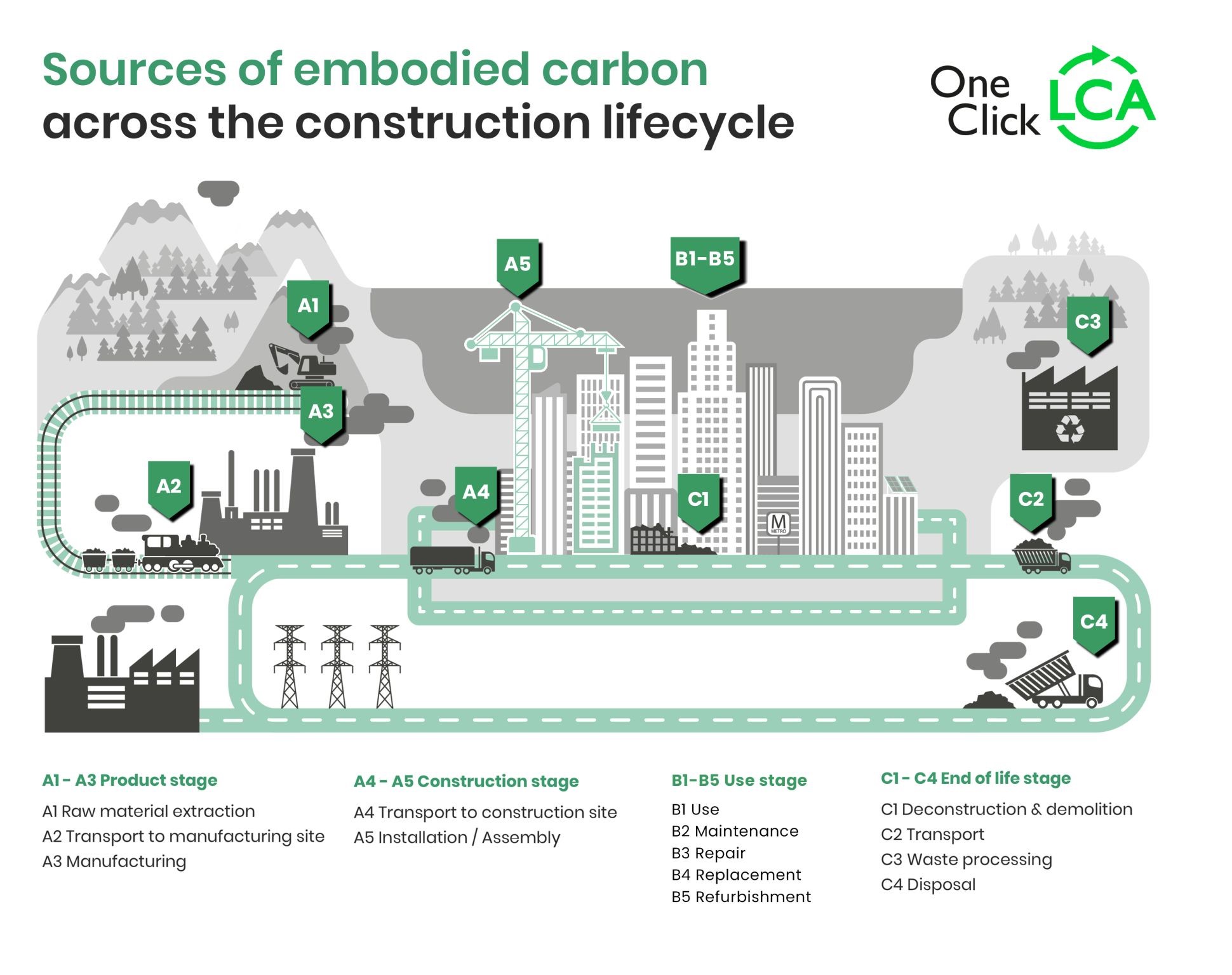

3. Life Cycle Assessment Stages A1–D according to standard EN 15804

The EN 15804 standard divides the product life cycle into modules from A to D, helping to standardize the assessment scope and make environmental impacts transparent.

The stages of a product life cycle assessment

Stage A: Product and Construction Stage

- A1 – Raw material supply: Includes the extraction of natural resources, preliminary processing, and energy consumption to create primary materials.

- A2 – Transport: Impacts from transporting raw materials to the factory (vehicle, distance, load).

- A3 – Manufacturing: The main production processes – consumption of electricity, water, fuel, as well as emissions and waste.

Stages A1–A3 are often called “Cradle-to-Gate” – this is the mandatory minimum scope in every EPD.

- A4 – Transport to the construction site: Includes transportation vehicles, fuel consumption, and distance.

- A5 – Construction and installation: Impacts from construction work, packaging disposal, construction waste, and energy consumption on-site.

Stage B: Use Stage

- B1 – Use: Emissions from the product during its use phase (if any).

- B2 – Maintenance: Cleaning, periodic maintenance (repainting, polishing, etc.).

- B3 – Repair, B4 – Replacement, B5 – Refurbishment: Activities related to repairing, replacing parts, or upgrading functions.

- B6 – Operational energy use: Electricity, gas, or other forms of energy.

- B7 – Operational water use: The amount of water consumed during the product’s operation.

🔹 Stage C: End-of-Life Stage

- C1 – Deconstruction: Dismantling the product from the building, including labor, machinery, and energy.

-

C2 – Transport: Transporting waste to a landfill or treatment facility.

- C3 – Waste processing: Sorting, cutting, grinding, and preliminary treatment for recycling.

- C4 – Disposal: Final disposal by incineration or landfilling, including generated emissions and leachates.

🔹 Stage D: Benefits and Loads Beyond the System Boundary

- Recognizes the potential benefits from reuse, recycling, or energy recovery. For example, recycled steel replaces virgin steel, helping to reduce future emissions.

- Although it is outside the system boundary, Stage D often plays a very important role in clarifying the overall environmental benefits.

4. Conclusion

Conducting an LCA and publishing an EPD is not just a trend but is gradually becoming a mandatory requirement in many export markets, for green building projects, and under ESG regulations. Especially in the fields of construction materials, furniture, and electronics, making the product life cycle transparent is a strategic step to enhance competitiveness and achieve sustainable development.